Engraving has existed for centuries from ancient craftsmen carving stone tablets to artisans etching metal plates for printing. But today, engraving is more advanced, more versatile, and more precise than ever before.

At Engrave Everything on Anything, we combine traditional craftsmanship with cutting-edge technology to turn ideas into art on any surface. Whether it’s a corporate plaque, a wedding keepsake, or a custom piece for your home, our goal is to deliver detail, durability, and beauty that stand the test of time.

This is a behind-the-scenes look at how modern engraving works and how we make your designs come to life.

🧭 A Blend of Art and Science

Engraving isn’t just a mechanical process. It’s a marriage between artistic design and technical precision. Every project starts with creativity understanding the story behind the design and ends with technology, ensuring that story is etched flawlessly into the material.

Modern engraving tools give us incredible flexibility, allowing us to work on nearly any surface:

- Wood

- Metal

- Leather

- Acrylic and plastics

- Glass and crystal

That’s why we say with confidence “If it can be engraved, we can engrave it.”

🔬 Step 1: From Concept to Design

Every engraving begins with an idea your idea.

Whether it’s a company logo, a personalized message, or a decorative pattern, we start by converting it into a digital design. Using specialized software, we fine-tune every line, font, and curve to ensure the engraving will look perfect on the chosen material.

Our Design Process Includes:

- Consultation: Understanding what you want to express a brand, a message, or an emotion.

- Mockups: Creating visual previews so you can see how your design will look.

- Material Testing: Adjusting size, depth, and layout to complement the texture and tone of the surface.

A good engraving design balances artistry and function, elegant, legible, and made to last.

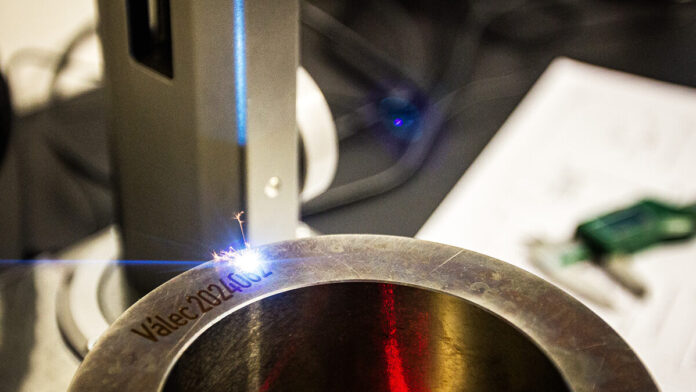

🔥 Step 2: Precision with Laser Engraving Technology

Laser engraving is the heart of modern engraving craftsmanship. Instead of cutting with a blade, a high-powered laser beam burns, melts, or vaporizes a thin layer of material to create a precise design.

Why Laser Engraving Stands Out

- Unmatched accuracy: Even the tiniest details are reproduced flawlessly.

- Permanent results: The design doesn’t fade, peel, or rub off.

- Versatility: Works on a wide range of materials from delicate glass to hard steel.

- Consistency: Perfect results, every single time.

With laser engraving, there’s virtually no limit to what we can create names, photos, barcodes, intricate artwork, or corporate logos.

💡 Did You Know?

Laser engraving can be accurate down to fractions of a millimeter that’s thinner than a strand of human hair!

🪚 Step 3: Material Matters

The surface you choose determines how your engraving will look and feel. Each material reacts differently to heat, depth, and light and we’ve mastered the art of adapting to them all.

Wood

Laser engraving on wood creates dark, rich contrasts that highlight the grain. Perfect for rustic, warm, or organic designs.

Metal

Laser marking on metals like stainless steel or aluminum creates crisp, permanent marks ideal for corporate branding and luxury gifts.

Leather

The laser lightly burns the surface to reveal a darker, textured effect, giving every item a handcrafted, premium finish.

Acrylic & Plastic

These materials engrave with clean, white or frosted effects, perfect for modern signage or promotional designs.

Glass

Engraving produces a soft, frosted texture that sparkles beautifully under light elegant for weddings, awards, and décor.

Each project requires custom settings, power, speed, and depth fine-tuned to ensure your engraving looks perfect and lasts a lifetime.

🧩 Step 4: Finishing and Quality Control

Once engraving is complete, we move into the finishing stage where craftsmanship meets perfectionism.

Our team carefully inspects each piece, removing residue, polishing surfaces, and ensuring that every letter and line is sharp. Nothing leaves our workshop without passing our quality checks.

We look for:

- Precision in every edge and curve

- Clean and consistent depth

- Perfect alignment and spacing

- Material finish free of scratches or burns

The result? A product that not only looks beautiful but feels professionally crafted.

🏆 Step 5: Personal Touches

This is where the “Everything on Anything” promise truly shines. Beyond the engraving itself, we customize every order to reflect your personal or business identity.

Examples of Finishing Touches

- Adding color fills to make engraved text stand out

- Mounting engraved plaques on wooden or metal backings

- Pairing engraved gifts with custom packaging or branding

- Combining engraving with cutting, etching, or printing for a multi-dimensional effect

Every detail matters because when you give or display something engraved, it represents you.

⚙️ The Tools Behind the Craft

At Engrave Everything on Anything, we use advanced equipment to guarantee precision and quality for every project.

Our Workshop Features:

- High-powered CO₂ lasers for wood, leather, and acrylic

- Fiber lasers for deep metal marking

- Rotary engraving tools for curved or irregular surfaces

- Design software suites for perfect digital layouts

We combine these technologies with years of craftsmanship ensuring that every engraving, no matter how small, carries the care and attention it deserves.

🔄 How Modern Engraving Differs from Traditional Methods

| Traditional Engraving | Modern Laser Engraving |

|---|---|

| Hand tools used to carve or scratch surfaces | High-precision lasers etch with light |

| Limited detail and speed | Extremely detailed, fast, and consistent |

| Suitable for soft materials only | Works on almost any surface |

| Labor-intensive and inconsistent | Automated yet artistically guided |

| Risk of wear or fading | Permanent and maintenance-free |

Modern engraving preserves the soul of traditional craftsmanship while introducing precision, efficiency, and creative freedom that were once impossible.

💼 Applications Across Industries

Laser engraving isn’t just for gifts or décor it’s transforming how industries brand, identify, and personalize their products.

Common Applications

- Corporate Branding: Logos, signage, awards, and promotional gifts.

- Industrial Use: Serial numbers, safety plates, and equipment labeling.

- Personalized Products: Jewelry, phone cases, keychains, and accessories.

- Events & Décor: Custom signage, invitations, and tableware.

- Art & Design: Sculptures, wall art, and creative displays.

Whether large-scale or small-batch, engraving adds authenticity, value, and identity.

🪄 Why Technology Doesn’t Replace Artistry

Even with all this technology, the heart of engraving is still human. Machines handle precision but we bring the vision.

Every font, layout, and depth decision is made by skilled artisans who understand how light, shadow, and texture interact. Technology is our tool but art remains our essence.

That’s what makes each piece from Engrave Everything on Anything more than just an engraved product it’s a reflection of craftsmanship and care.

🌟 Sustainability and Quality

Modern engraving is also eco-friendly. Unlike printing, which uses inks or chemicals, laser engraving uses only light. There are no dyes, no solvents just precision and permanence.

This means our work is both sustainable and safe for the environment, aligning with modern values of quality and responsibility.

✍️ Final Thoughts Engraving the Future

The engraving industry has evolved from hand chisels to high-powered lasers, but the essence remains unchanged to make marks that last forever.

At Engrave Everything on Anything, we take pride in blending modern technology with timeless artistry. Each project is a partnership — between our tools, our hands, and your imagination.

From concept to creation, we don’t just engrave objects we engrave emotions, milestones, and identities.

Because true craftsmanship isn’t about the machine; it’s about the meaning behind every mark.

✨ Engrave Everything on Anything Precision. Passion. Permanence.